Introduction

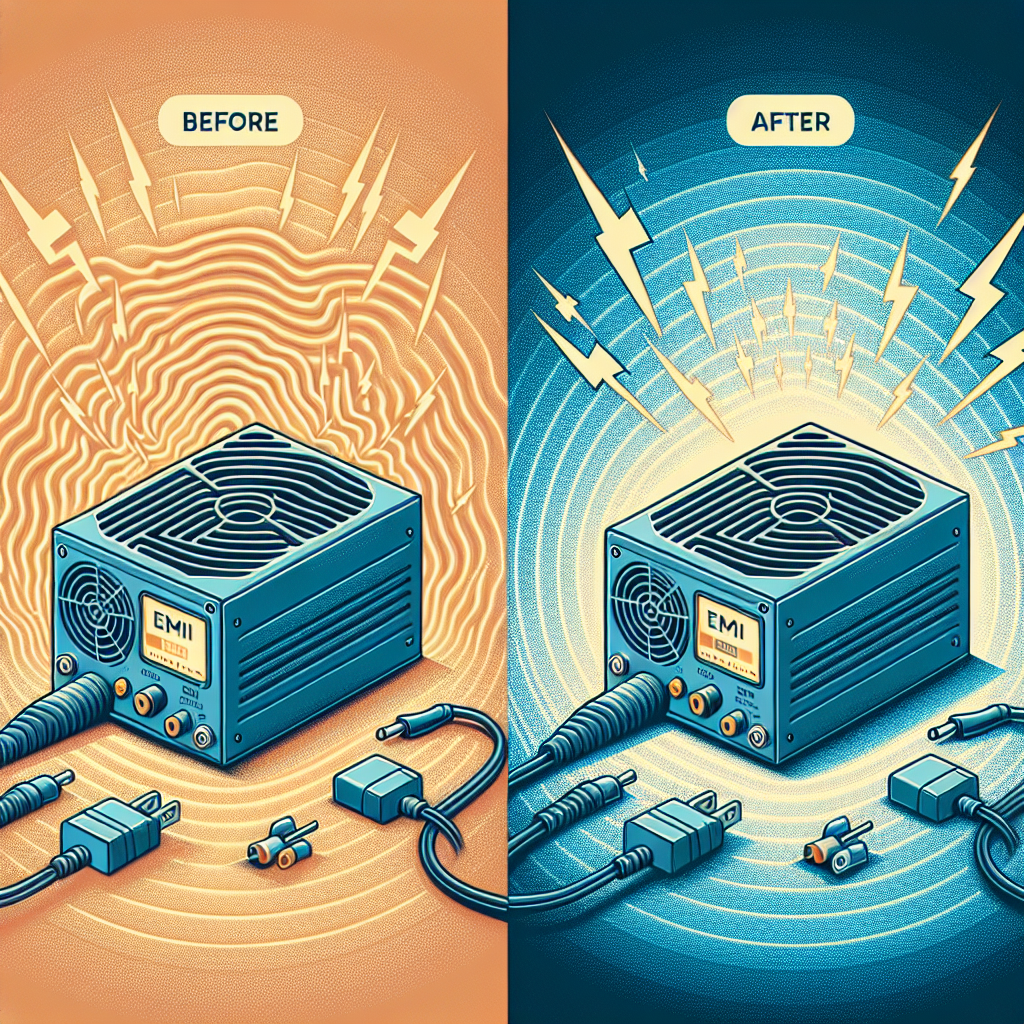

Electromagnetic Interference (EMI) is a phenomenon that affects electronic devices and systems, potentially causing malfunction or degradation of performance. In the realm of power supplies, the significance of EMI filtering cannot be overstated. EMI filtering plays a critical role in ensuring that power supplies function as intended, without generating or being affected by unwanted electrical noise. This article delves into the importance of EMI filtering in power supplies, examining its impact on device performance, safety, and compliance with regulatory standards.

What is EMI?

Electromagnetic interference refers to the disturbance that electromagnetic fields can cause to electronic equipment. EMI can originate from various sources, including:

- Natural Sources: Lightning, solar flares, and cosmic radiation.

- Man-Made Sources: Motors, transformers, and other electrical devices.

Understanding the sources of EMI is important for recognizing the need for effective filtering solutions in power supplies.

Importance of EMI Filtering

EMI filtering is crucial for several reasons:

- Performance: Filters help maintain signal integrity by reducing noise, which can degrade performance.

- Safety: Proper filtering can prevent electrical shock and ensure that devices operate safely without risk to users.

- Regulatory Compliance: Many industries have strict regulations concerning EMI emissions. Filters help meet these standards.

Types of EMI Filters

EMI filters can be classified into several categories based on their configuration and function:

1. Low-Pass Filters

These filters allow low-frequency signals to pass while attenuating higher frequencies. They are commonly used in power supplies to suppress high-frequency noise.

2. High-Pass Filters

High-pass filters block low-frequency signals and allow higher frequencies to pass. They are less common in power supplies but can be useful in specific applications.

3. Band-Pass Filters

These filters allow a specific range of frequencies to pass while attenuating frequencies outside that band. They are typically used in communication systems rather than in standard power supplies.

4. Common-Mode Filters

These filters address noise that appears on both the input and output lines, helping to isolate the power supply from external disturbances.

5. Differential-Mode Filters

These filters deal with noise that affects the two lines of a circuit differently, providing a crucial function in reducing EMI.

Table: Comparison of EMI Filter Types

| Type | Pass Band | Application |

|---|---|---|

| Low-Pass | Low Frequencies | Power Supplies |

| High-Pass | High Frequencies | Specific Applications |

| Band-Pass | Specific Range | Communication Systems |

| Common-Mode | Both Lines | Isolation from Disturbances |

| Differential-Mode | Two Lines Differently | Noise Reduction |

Impact on Device Performance

EMI filtering directly influences the performance of electronic devices. Here’s how:

- Signal Integrity: Filters clean up the signal, ensuring that the devices interpret data correctly, which is especially vital in high-speed applications.

- Reduced Error Rates: A system with effective EMI filtering experiences fewer errors, leading to enhanced reliability.

- Increased Lifespan: By mitigating stress from EMI, filters help prolong the life of sensitive electronic components.

Impact on Safety

Safety is paramount in electrical applications, and EMI filtering contributes significantly by:

- Protecting Human Operators: Filters help prevent electrical shock hazards and ensure safe operation of devices.

- Preventing Equipment Damage: By reducing EMI, filters minimize the risk of damage to more sensitive equipment.

- Enhancing Fire Safety: Less electrical noise means fewer chances of overheating and potential fires.

Regulatory Compliance

Many industries are governed by regulations requiring compliance with specific EMI standards. These include:

- FCC Part 15: In the United States, this regulation deals with unintentional radiators and encourages devices to limit EMI emissions.

- IEEE Standards: The Institute of Electrical and Electronics Engineers provides standards for electromagnetic compatibility, guiding manufacturers on designing EMI-compliant devices.

- EN Standards: In Europe, standards such as EN 55032 dictate limits for the electromagnetic emissions of multimedia equipment.

Design Considerations

When integrating EMI filtering into power supply design, certain factors must be taken into account:

- Frequency Range: Understanding the frequency spectrum of potential EMI sources helps in selecting the right filter.

- Filter Specifications: The chosen filter must meet both the technical requirements and the noise reduction levels needed.

- Size and Cost: Filters can vary significantly in size and cost, so these factors must be weighed against performance needs.

Conclusion

In conclusion, EMI filtering is a vital aspect of power supply design that affects performance, safety, and compliance with regulatory standards. By mitigating unwanted electromagnetic interference, filters ensure that electronic devices operate effectively and reliably, while also protecting users and equipment. As electronic devices become increasingly complex and intertwined in daily life, the role of EMI filtering will continue to grow in importance. Manufacturers must prioritize the integration of effective EMI filtering solutions to maintain not only operational functionality but also compliance with industry regulations.